|

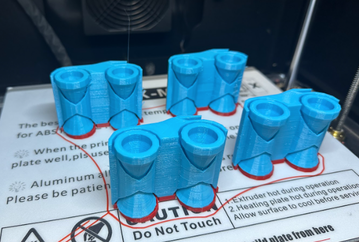

Overview and Purpose We envisioned the development of a model to transform plastic bottle caps into useful products to tackle plastic pollution and support underserved communities. We hoped to find opportunities to recycle plastic by 3D printing and create valuable products. The project aimed to increase the accessibility of recycling a protocycler, a machine that transforms plastic waste into valuable 3D printer filament, which can be used to create products that are helpful for those in need. Our team supported Arizonans for Children by creating 3D-printed toy cars for kids in foster care.  Our Project Partner Our project partner was Tyler Eglen, Associate Project Manager at Rob and Melani Walton Sustainability Solutions Services. He also has his own 3D print lab on the ASU Polytechnic campus.  Our Project's "Why" Our project uses a circular economy, which means turning waste into valuable products, therefore all materials are used and there is no waste. We had to troubleshoot to assess creative ways to recycle plastic using a protocycler since it is hard to recycle in the Materials Recovery Facility (MRF). We also wanted to provide support for local communities in need by using 3D printing. We collaborated with Arizonans for Children, an organization working with children in foster care in Arizona. They needed more toy cars for their children to play with. Our project supports the UN’s Sustainable Development Goal #12 because it ensures sustainable consumption and production. More specifically, it supports target 12.5 i.e., by 2030, substantially reduce waste generation through prevention, reduction, recycling, and reuse. Our Strategy Step 1: Establish a partnership with a nonprofit organization Step 2: Research product designs for 3D printer Step 3: Confirm printed product design Step 4: Research Protocycler Step 5: Troubleshoot Protocycler Step 6: Create 3D-printed products Since Arizonans for Children was in need of toy cars, we researched different car designs before landing on one that we felt provided the most function and could be easily mass-produced. Then, we spent 50 hours troubleshooting the protocycler and 3D printer and created a How-To guide for both machines. Finally, we 3D printed 32 toy cars and distributed them to the organization's facility. Our Objectives and KPI's Objective 1: Partner with a nonprofit organization. KPI: Reach out to 12 different organizations; 3 per person Objective 2: Print and distribute chosen project design. KPI: 30 total cars Objective 3: Become sufficient using the Protocycler. KPI: 50 hours total; 12.5 hours per person  Troubleshooting

Results

1 Comment

4/4/2023 05:26:15 pm

Sustainability is about meeting the needs of the present without compromising the ability of future generations to meet their own needs, and it involves balancing economic, social, and environmental factors to create a world that is livable for everyone, both now and in the future.

Reply

Leave a Reply. |

Archives

July 2024

Categories |

|

RECEIVE GREENLIGHT NEWS

|

© GreenLight Solutions. All rights reserved.

|

RSS Feed

RSS Feed